I can tell you that from my training as a chef, that sniff testing is complete and utter bullshit.

Any chef or cook knows that seafood, especially processed seafood, can smell...questionable.....at any given time. Unfortunately the majority of seafood sold to restaurants has been treated, frozen, sometimes thawed and frozen by accident several times.

As a few examples:

Ahi Tuna steaks served by most restaurants....nice and pink..

.....It's gassed on the boat at sea with carbon monoxide to keep the flesh from oxidizing and turning brown, then flash-frozen. Yum.

Scallops, nice and juicy tender ...

....wet-packed with tri-sodium phosphate for moisture retention ( read=adding weight to the product in the form of water )

Black Tiger shrimps from Thailand, sweet and meaty

...Thai fishermen are fond of pouring a little bit of diesel fuel into their catch holds to prevent seafood from rotting when there is no refrigeration available on the vessel, common.

........So the truth of the matter is that if you are used to cooking with things that already have a "funny smell", then sniff testing is pointless.

Now, let's ask some crucial questions :

Has the testing taken into account that there are various types of fish ?

Has the testing examined the various parts of the fish ?

How has testing declared seafood safe to eat, when there are no previous studies to go by ?

Why is only "sniff-testing" being suggested ?

Has NALCO been asked for the proprietary information about COREXIT's constituents ?

Fatty fish don't get around too much, lean fish are travelers. It's like the difference between farm-raised salmon and wild-caught salmon. Farm raised salmon are much fattier, they don't have too many chances to get exercise, hence the fat.

There has been no testing of various parts of the fish....when I get a whole fish, I break it down, and usually make a nice fumet out of the body and head ( stock )...although not always the heads, depends on the fish I am using.

Large processing operations and small processors alike, sell their scraps. If you are on the coast, most likely, you can get fish bodies for stock from your local purveyor.

Larger plants will sell their scraps for pet food, fertilizer, and ........cooking into commercial soup bases, which many restaurant sadly use these days to make soups, stews and sauces.

Pollutants tend to bio-accumulate in different areas of an organism, fatty tissues are a favorite location, but organs like the liver are prime targets too.

Until I see some shrimp, scallops, and whole fish, split head to tail and examined under UV light for presence of hydrocarbons, I will be suspicious. ...and I'm sure, given modern technology, that we can come up with a better testing method....

..... like I tell people, " if you don't mind, than it doesn't matter ".

Wednesday, August 18, 2010

New system in development..seems familiar in concept to something...oh yeah, I remember..

........My idea for containing the wellhead.

...Although different in design, exactly the same in concept.....large heavy box with the ability to capture oil.

You can bet I will keep track of this "new" developing technology, just out of curiosity of course.

The following is from the Oil Drum

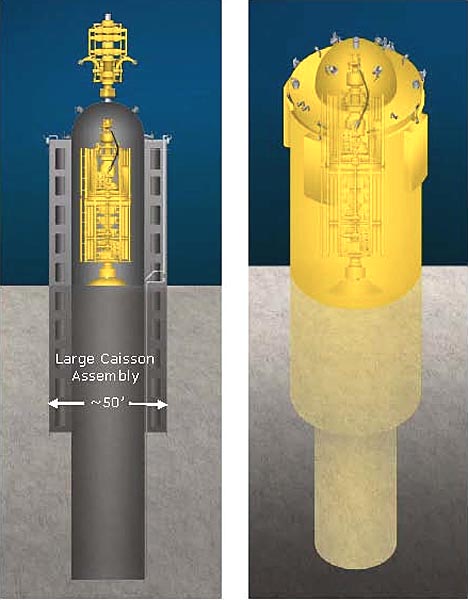

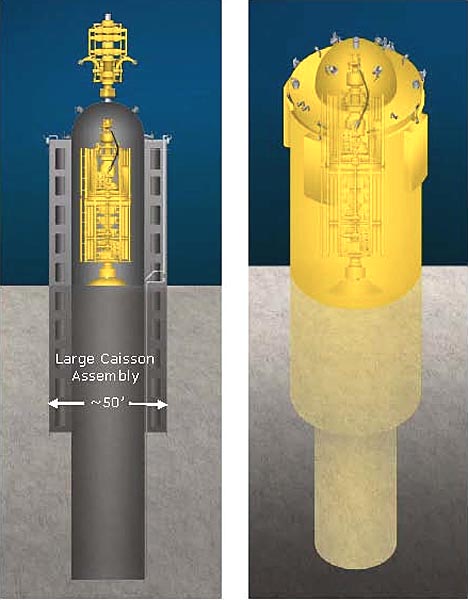

" If the integrity of the end of the well is compromised (i.e. the rock fragmented, the liners broken or the wellhead destroyed in some way), then a different approach will be required.

Here a caisson assembly will be constructed around the remnant BOP, large enough to surround the well at a point where the rock has enough strength and quality to allow a seal under the wall. This will then allow a cap to be placed on top of the caisson, with the containment system from the last slide, mounted on top of the cap, as a way of capturing the hydrocarbons that are bled off from the well, without their coming into contact with the seawater, and forming hydrates. "

(ExxonMobil )

----------------------------------------------------------------------------

Lol, Isaac wants royalties....or some help getting student loans to study engineering...hint hint

...Although different in design, exactly the same in concept.....large heavy box with the ability to capture oil.

You can bet I will keep track of this "new" developing technology, just out of curiosity of course.

The following is from the Oil Drum

" If the integrity of the end of the well is compromised (i.e. the rock fragmented, the liners broken or the wellhead destroyed in some way), then a different approach will be required.

Here a caisson assembly will be constructed around the remnant BOP, large enough to surround the well at a point where the rock has enough strength and quality to allow a seal under the wall. This will then allow a cap to be placed on top of the caisson, with the containment system from the last slide, mounted on top of the cap, as a way of capturing the hydrocarbons that are bled off from the well, without their coming into contact with the seawater, and forming hydrates. "

----------------------------------------------------------------------------

Lol, Isaac wants royalties....or some help getting student loans to study engineering...hint hint

Subscribe to:

Comments (Atom)